About Us

Ningbo QiXing Pneumatic Technology Co., Ltd. is a powerful enterprise integrating Research and Development, Production, and Trading with a history of 20 years. We are located in Ningbo Zhejiang, on the eastern coast of China. With Convenient transportation and rich resources.

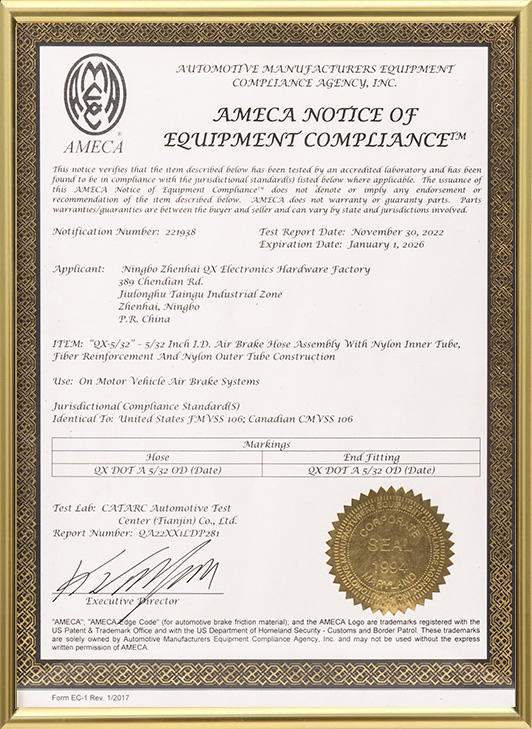

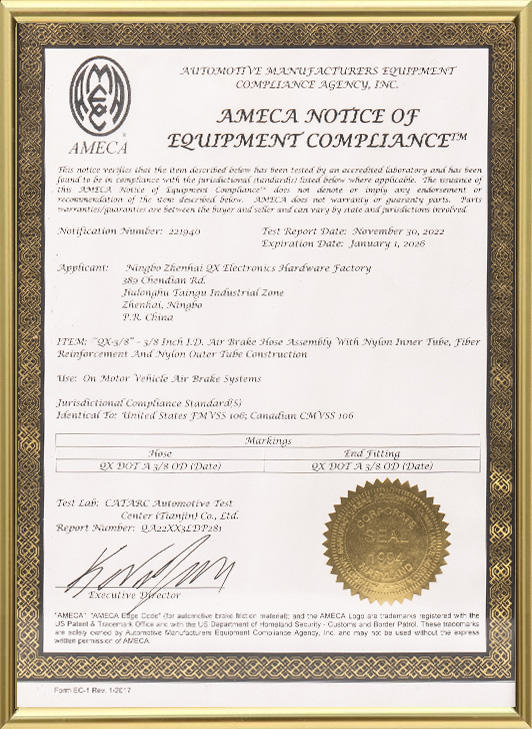

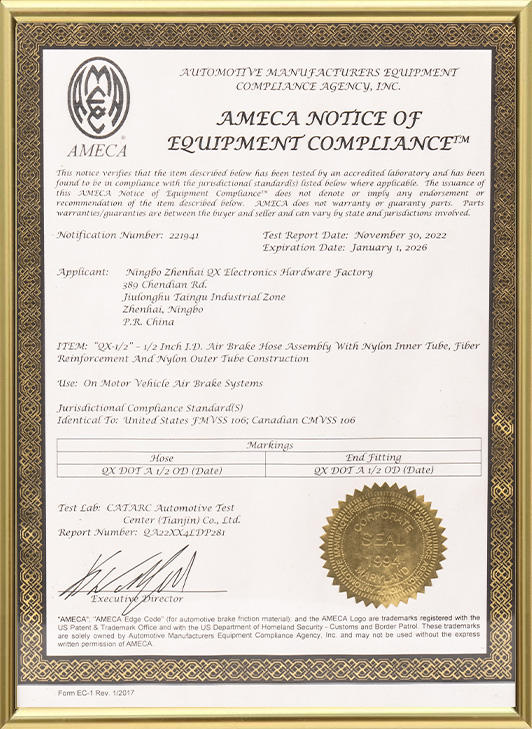

We have advanced production equipment and experienced product design and production. In 2003, we began to do research and manufacturing based on pneumatic connectors. After nearly 20 years of development, we have formed many special product lines which mainly consist of BRASS DOT FITTINGS, DOT ferrule connectors, PUSH-IN fittings, and composite fittings. The product is diversified in shape including in-line straight, right-angle, threaded, three-way T-type, and ordinary comprehensive series fittings. We also make customized products for our customers from all over the world according to their samples and pictures.

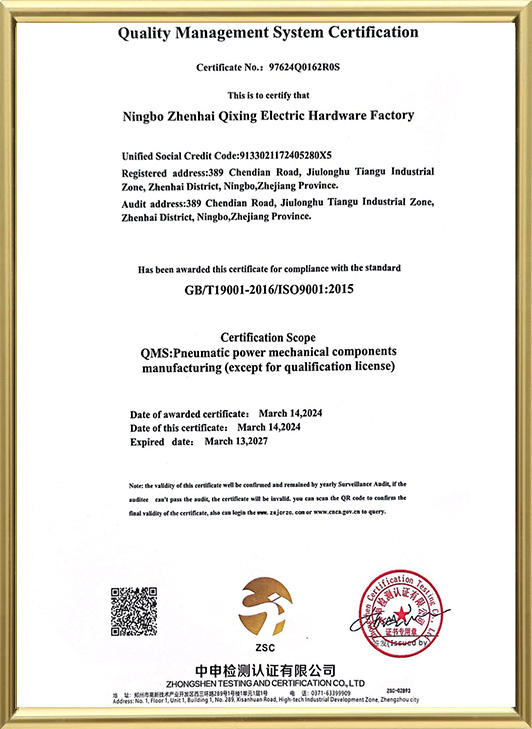

On the other hand, we have advanced technology and strong management. Based on the principles of quality and technological innovation, Improving technology and production continually leads our products to sell well in the US and European markets.

Our company promises that we can offer short production cycles, high quality and reasonable price products, and great service in pre-sales and after-sales.In terms of cooperation, we are based on the principle of meeting customer needs and acting with integrity. We are looking forward to receiving your inquiries soon. We look forward to working with you for a better tomorrow!